LU-600

Product Overview

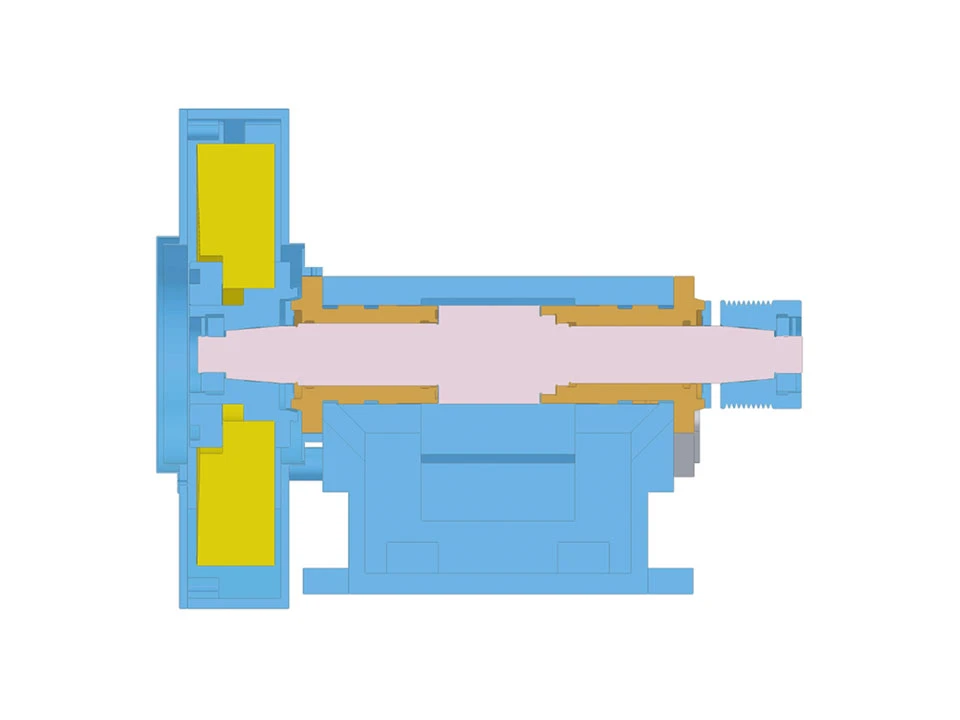

LU-600 CYLINDRICAL GRINDING MACHINE

Key Features

Stable and rigid spindle head

The spindle runs on precision bearings, assuring maximum spindle stability. It guarantees outstanding grinding accuracy for external dia., internal dia. (optional) & end face.

Special hydrostatic bearing

The wheel spindle runs by using a special hydrostatic bearing and is especially ideal for precision grinding work. It features high speed, no friction between metals, no heat generation, deformation-free, extra high accuracy and continual use.

Precision wheel head

The grinding wheel spindle is precision machined from high quality alloy steel, normalized, tempered, carburized and sub-zero treated, precision ground and mirror-effect treated.

Various grinding application

One grinder allows straight plunge grinding, shoulder grinding, traverse grinding, end face grinding, taper grinding & internal grinding (optional) functions for different machining purpose.

Technical Specifications

| Specification | LU-600 |

|---|---|

| CAPACITY | |

| Distance between center | 610 mm |

| Height Center | 130 / 150 / 180 / 200 mm |

| Table | |

| Swivelling Angle | +7, -5 Deg |

| Table speed mech 4 Step | 140 – 700 (VFD) Mm/min |

| Electric motor req. 3phase | 0.5/1440 Hp/rpm |

| Hy Speed Infinitely variable | 0.1 to 2.5 Met/min |

| Hy Power pack Electric Motor, 3phase | 1 / 1440 Hp/rpm |

| Grinding Wheel Size DxWxB | 350 x 40 x 127 mm |

| Grinding Wheel Speed | 1700 rpm |

| In Feed of hand wheel per division | 0.01 mm |

| Electric motor Req. 3phase | 3 / 1440 Hp/rpm |

| Rapid approch | 40 mm Stock (F x R) mm |

| Spindle Speed | 65 –300 (VFD) mm |

| Spindle in Taper | 4 M. T. |

| Electric motor 3phase | 1.5 / 960 Hp / rpm |

| Taper in Quile | 4 M. T. |

| Max. quile stock | 40 mm |

| Spindle Size | 250 x 60 mm |

| Spindle Speed | 16000 rpm |

| Electric motor Req. 3phase | 1 / 2800 Hp / rpm |

| Coolant Tank | 50 Litre |

| Coolant Pump 3phase | 0.15 Hp |

The mentioned specifications & dimensions are subject to change without notice.

Accessories

Standard Accessories

- Grinding Wheel with Flange

- Balancing Blocks

- Universal Wheel Head Slide

- Dead Centers 2 Nos. (MT-4)

- Wheel Head Motor & Work Head Motor

- Coolant Tank with Pump and Piping

- Dressing Attachment

- Safety Splash Guard

- Wheel Flange Extractor

- V-Belts and Pulley Cover

- Lubricants Oil Pump

- Electric Panel with Push Buttons

- VFD (for Work Head)

- Machine Lamp

- Turcite Coated Slide

Optional Accessories

- Mechanical Self Feeding Attachment

- Internal Attachment

- Three Point Steady Rest

- Two Point Steady Rest

- True Chuck Flange

- Additional Wheel Flange

- Wheel Balancing Arbor

- Wheel Balancing Stand

- Magnetic Separator

- Hydraulic Attachment

- Rapid Approach

- Duell Timer

- Tail Stock Hydraulic

- Automatic Lubrication Oil Pump

- Micro Feeding Attachment

- PLC Single Axis with Touch Screen